Key Takeaways

Murky pond water is caused by excess waste, poor circulation, stirred-up sediment, or nutrient overload.

Water color matters: green = algae, brown = sediment, cloudy = particles or imbalance.

Quick fixes: skim debris, add beneficial bacteria, clean filters, and do small water changes.

Long-term clarity comes from strong filtration, aquatic plants, and good circulation.

Natural methods like snails, submerged plants, and barley straw, support a balanced ecosystem.

Stay consistent: test water, feed fish wisely, and adjust care with the seasons.

Call a pro if the water stays murky or fish show signs of stress.

Clear Water Naturally in Your Ornamental Pond

Every single day, water treatment plants across the globe process billions of gallons of water. Hidden behind the scenes is a substance that plays a pivotal role in ensuring the water we drink, bathe in, and use for industry is clean and safe: the coagulant.

Coagulants are essential chemicals that make this transformation possible, yet few of us stop to think about their impact. In this blog, we’ll uncover the science behind coagulants, the different types available, and their importance across a variety of industries. By the end, you’ll have a newfound appreciation for these invisible heroes of water treatment.

What Is a Coagulant?

Let’s start simple. A coagulant is a chemical or natural substance that facilitates the removal of suspended particles from liquids, primarily water.

Suspended particles can include anything from dirt and organic matter to bacteria and industrial pollutants. Coagulants work by neutralizing the electrical charges on these particles, which typically repel each other, allowing them to clump together into larger masses, or flocs. This process, known as coagulation, is the first step in many water treatment processes.

Without coagulants, water would remain cloudy, filled with impurities that are impossible to filter efficiently. These substances aren’t just about aesthetics, they’re critical for ensuring water quality meets safety and environmental standards.

How Do Coagulants Work?

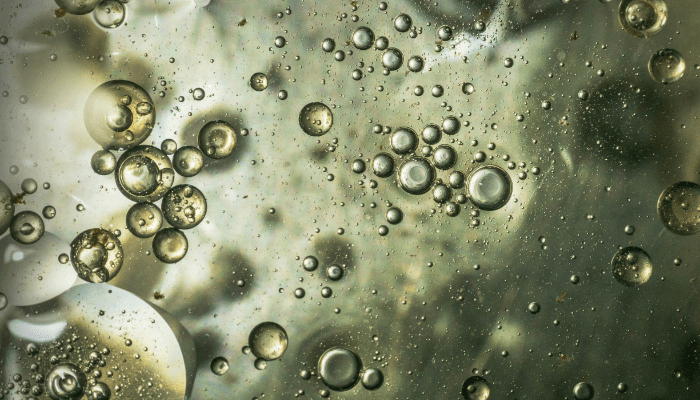

Here’s the science in action: most particles in water have a negative surface charge, causing them to repel each other and remain suspended. Coagulants, which are often positively charged, neutralize this charge, destabilizing the particles. Once destabilized, the particles attract each other, forming clumps (or flocs) large enough to be removed via sedimentation or filtration.

This process happens in three stages:

- Coagulation: Coagulants are added to destabilize particles.

- Flocculation: Gentle mixing encourages the particles to form larger clusters.

- Separation: The larger flocs are removed from the water through settling, filtration, or flotation.

The result? Clearer, cleaner water ready for its next step, whether that’s distribution for drinking or further industrial processing.

Types of Coagulants

There’s no one-size-fits-all when it comes to coagulants. Different applications and water types require specific coagulants tailored to their unique challenges. Here are the three primary types.

1. Inorganic Coagulants

These are the most commonly used coagulants in water treatment. They include aluminum and iron-based compounds, such as:

- Aluminum Sulfate (Alum): Widely used for municipal water treatment, it’s effective but can leave behind residual aluminum.

- Ferric Chloride and Ferric Sulfate: Known for their efficiency in a wide pH range, these coagulants are commonly used in wastewater treatment.

- Polyaluminum Chloride (PAC): A versatile coagulant with reduced sludge production.

Inorganic coagulants are cost-effective, but they can result in higher sludge volumes, requiring additional disposal steps.

2. Organic Coagulants

Organic coagulants are synthetic polymers, often used as alternatives or supplements to inorganic coagulants. Examples include:

- Polyamines: Effective at neutralizing charges and forming stable flocs.

- PolyDADMAC: A highly efficient coagulant used for water treatment and industrial processes.

Organic coagulants generate less sludge, making them ideal for applications where waste management is a concern.

3. Natural Coagulants

Eco-conscious industries are turning to natural alternatives. These coagulants, derived from plants or other organic sources, are gaining traction due to their sustainability. Examples include:

- Moringa Seeds: Widely used in developing regions for water purification.

- Chitosan: Derived from crustacean shells, it’s biodegradable and effective in low-to-moderate turbidity water.

Natural coagulants may not yet match the efficiency of chemical options in all scenarios but are promising for low-impact applications.

Applications of Coagulants

Coagulants are indispensable across multiple industries, ensuring clean water and efficient processing. Here’s a closer look.

1. Water and Wastewater Treatment

This is the most well-known application. Coagulants remove impurities from raw water, making it safe for consumption. They also play a critical role in treating industrial wastewater, reducing pollutants before discharge or reuse.

2. Food and Beverage Industry

In food production, coagulants are used to clarify liquids like juices and sugar syrups, ensuring purity and consistency.

3. Other Industrial Uses

From oil refining to paper manufacturing, coagulants are essential for separating unwanted particles and streamlining production processes.

Choosing the Right Coagulant

Selecting the correct coagulant depends on several factors:

- Water Type: Is the water high in turbidity, or does it contain organic pollutants?

- Desired Outcome: Are you aiming for ultra-clear water or simply meeting regulatory standards?

- Cost and Efficiency: Some coagulants are more cost-effective but may produce more sludge, requiring additional disposal costs.

Pilot testing is often necessary to determine the most effective coagulant and dosing strategy for a given application.

Advantages and Limitations of Coagulants

Advantages

- Efficiency: Coagulants remove particles quickly and effectively, even in high volumes.

- Versatility: They can be tailored to work across diverse applications.

- Cost-Effective: For large-scale water treatment, coagulants provide excellent value.

Limitations

- Sludge Generation: Inorganic coagulants can produce significant sludge, requiring disposal.

- Residues: Improper dosing can leave chemical residues, which may affect water quality.

- Environmental Impact: While necessary, some coagulants can have environmental downsides, pushing the need for greener alternatives.

Coagulants vs. Flocculants: What’s the Difference?

While coagulants and flocculants often work hand-in-hand in water treatment, their roles are distinct and complementary.

Coagulants act first, targeting the electrical charges that keep fine particles suspended in water. These charges, often negative, cause particles to repel each other. By neutralizing the charges, coagulants destabilize the particles, allowing them to come closer together. However, at this stage, the particles are still too small to settle or filter effectively.

That’s where flocculants come in. Flocculants work by binding these destabilized particles together into larger clusters, or flocs. These chemicals often contain long-chain polymers that physically bridge the particles, making them heavier and easier to separate from the liquid. The flocculation process typically involves gentle mixing to encourage particle bonding without breaking up the forming clusters.

In short, coagulants start the process by destabilizing particles, while flocculants finish it by creating large, cohesive flocs. Together, they make it possible to remove impurities efficiently, whether through sedimentation, flotation, or filtration.

This tandem approach is critical for producing clear, clean water in everything from municipal treatment plants to industrial wastewater systems.

Conclusion

The coagulant industry is evolving. Sustainable solutions, like bio-based coagulants, are gaining momentum as industries prioritize reducing their environmental footprint.

Advances in polymer chemistry are producing more efficient, residue-free options, and digital monitoring systems are enabling real-time optimization of coagulant usage. The future looks bright for greener, smarter water treatment solutions.

Coagulants might not grab headlines, but their impact is monumental. From making water safe to supporting industrial processes, they’re essential to modern life. By understanding their role, types, and applications, we can make informed choices that balance efficiency, cost, and sustainability.

Whether you’re a professional in water treatment or simply curious about what keeps your tap water clear, coagulants are worth celebrating. The next time you see sparkling water, remember: there’s science behind the clarity!

Want water clarity without chemicals?

Discover our natural filtration and eco-friendly water solutions and see how we help ponds, pools, and water systems stay clean the natural way. Safe for people, safe for the planet.

FAQ

What is the definition of a coagulant?

A coagulant is a substance that helps particles clump together, forming larger aggregates for easier removal, often used in water treatment.

What is coagulant used for?

Coagulants are primarily used in water and wastewater treatment to remove impurities, but they also play roles in food and industrial processes.

What is an example of a coagulant?

Alum (aluminum sulfate) is a common example of a coagulant used in water treatment.

What is coagulant food?

Coagulant food refers to substances like rennet or calcium sulfate used to thicken or solidify food, such as in making cheese or tofu.